Shedding light on phosphors

News category: Nanotech

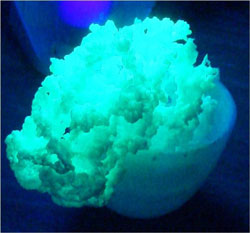

Glow-in-the-dark phosphors could be used to paint the walls of housing in underprivileged areas, giving occupants safe light at night. This meringue of glow-in-the dark phosphors was made by combusting chemicals at 700°C with a fuel (like urea), and is then ground into a powder.

Glow-in-the-dark phosphors could be used to paint the walls of housing in underprivileged areas, giving occupants safe light at night. This meringue of glow-in-the dark phosphors was made by combusting chemicals at 700°C with a fuel (like urea), and is then ground into a powder.

From alarm clocks to traffic lights, computers, cellphones and radios, phosphors have a vital function in modern display technology. Life as we know it is unimaginable without them. But we take phosphor technology for granted. Where in the world do these special little lights come from?

Phosphors bring light into our world. Mostly they form part of light emitting diodes (LEDs), laptop and cellphone screens, or glow-in-the-dark objects. By the time you see them, they’ve been on an incredible journey that most of us are oblivious to.

These tiny particles (nanometres or micrometres in size) are made of various elements blended together in a precise mix to emit an exact colour of light. These elements may be familiar – like sulphur, oxygen and zinc – or less well-known – like terbium and yttrium. Adding or removing one element can change the colour or the length of time the phosphor keeps on glowing.

Phosphors are made through lots of experimentation, and some extreme techniques. These include making a solution of chemicals that turn into a gel, or combusting chemicals to form what is called a meringue. Some chemicals are simply baked, with temperatures as high as 1 600°C fusing them together. Once the phosphors have been ground into a powder, they may be melted and vaporised so they settle evenly on a thin film, like that used for your laptop screen.

Scientists such as Professor Hendrik Swart and Professor Martin Ntwaeaborwa at the University of the Free State are dreaming of a world in which we can paint our roads and walls with glow-in-the-dark phosphors. For this to happen, phosphors will need to become far cheaper to make, so it’s time for some new innovations in this area.

Writer: Febe Meyer

Reviewed by: Prof Hendrik Swart and Prof Sabelo Mhlanga